how to test machine coolant with a refractometer|refractometer conversion chart for coolant : wholesalers Coolants must operate within a specific concentration window to maintain the right amount of lubricity and additive content. Refractometers are instruments used to obtain a °Brix reading, which measures the oil content present in a coolant mixture. Un autoclave es un dispositivo que esteriliza con alta temperatura y presión. Conozca sus partes, los tipos que existen y algunas industrias que lo usan.Autoclaves SM200/300/500/510 These models are automatic high-pressure steam sterilizers with an interactive key input system, which makes it possible to sterilize and dry .

{plog:ftitle_list}

Autoclaved Aerated Concrete Masonry Units (AAC) are ultra lightweight concrete blocks with a unique cellular structure that provides superior energy efficiency, fire resistance .The unit weight of an AAC (Autoclaved Aerated Concrete) block can vary depending on its dimensions and specific composition. On average, the unit weight ranges from about 550 to 650 kg/m³ (30 to 34 pounds per cubic .

TEST your coolant. Using a dropper, extract coolant from your machine. Again using the dropper, place 2–3 drops of coolant onto the prism of the refractometer and carefully secure its cover plate. Make sure there are no dry spots or air bubbles beneath the cover . Refractometers for Metalworking Fluids (Coolant) - hand-held optical brix-based .

TEST your coolant. Using a dropper, extract coolant from your machine. Again using the dropper, place 2–3 drops of coolant onto the prism of the refractometer and carefully secure its cover plate. Make sure there are no dry spots or . Refractometers for Metalworking Fluids (Coolant) - hand-held optical brix-based refractometer to measure coolant concentration Calibration is easy. Mix a small batch with a measuring cup and test it to see what the refractometer reads. Coolants must operate within a specific concentration window to maintain the right amount of lubricity and additive content. Refractometers are instruments used to obtain a °Brix reading, which measures the oil content present in a coolant mixture.

To test coolant with a refractometer, follow these steps: Extract coolant or fluid from your machine using a dropper. Place 2–3 drops of coolant onto the prism of the refractometer and secure its cover plate.Here is a video of how to properly check coolant concentration using a refractometer. We have partnered with Eastern Oil Company to provide a free 5 gallon b.There are two handheld refractometers for use on the shop floor: analog and digital. Most maintenance personnel and machinists are familiar with the analog refractometers: flip-up lens cover, add a drop of coolant, close the lens cover, look through the eyepiece and read the scale.Using a Refractometer: Check the calibration of your refractometer. Water at 68° F should read 0.0 percent Brix. Open the cover plate and place a drop of plain water (no coolant) on the prism surface (see Figure 1). Close the cover plate to spread water over surface.

54. 6.9K views 7 years ago. Lesson objectives include interpretation of a coolant manufacturer datasheet, concentrate proportions and measurement, mixing technique, sampling, and measuring the. Maintaining the proper concentration of coolant is essential to ensure consistent machining performance and to prolong the life of the machine and its tools. In this guide, we’ll explain how CNC coolant refractometers work, as well as .

A refractometer is an essential tool for accurately measuring the concentration of your coolant mixture. Here’s how to use it: Calibrate the Refractometer: Before taking any measurements, calibrate your refractometer using distilled water. TEST your coolant. Using a dropper, extract coolant from your machine. Again using the dropper, place 2–3 drops of coolant onto the prism of the refractometer and carefully secure its cover plate. Make sure there are no dry spots or . Refractometers for Metalworking Fluids (Coolant) - hand-held optical brix-based refractometer to measure coolant concentration Calibration is easy. Mix a small batch with a measuring cup and test it to see what the refractometer reads.

Coolants must operate within a specific concentration window to maintain the right amount of lubricity and additive content. Refractometers are instruments used to obtain a °Brix reading, which measures the oil content present in a coolant mixture.To test coolant with a refractometer, follow these steps: Extract coolant or fluid from your machine using a dropper. Place 2–3 drops of coolant onto the prism of the refractometer and secure its cover plate.

Here is a video of how to properly check coolant concentration using a refractometer. We have partnered with Eastern Oil Company to provide a free 5 gallon b.There are two handheld refractometers for use on the shop floor: analog and digital. Most maintenance personnel and machinists are familiar with the analog refractometers: flip-up lens cover, add a drop of coolant, close the lens cover, look through the eyepiece and read the scale.Using a Refractometer: Check the calibration of your refractometer. Water at 68° F should read 0.0 percent Brix. Open the cover plate and place a drop of plain water (no coolant) on the prism surface (see Figure 1). Close the cover plate to spread water over surface.

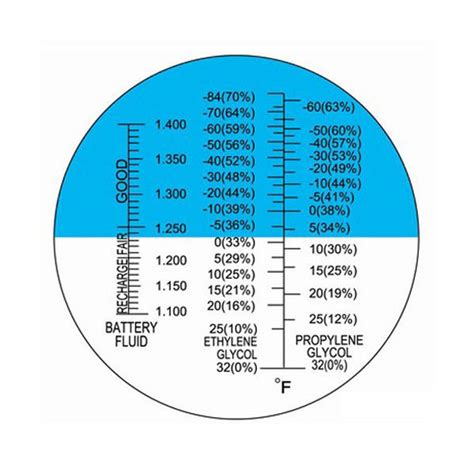

refractometer reading chart

54. 6.9K views 7 years ago. Lesson objectives include interpretation of a coolant manufacturer datasheet, concentrate proportions and measurement, mixing technique, sampling, and measuring the. Maintaining the proper concentration of coolant is essential to ensure consistent machining performance and to prolong the life of the machine and its tools. In this guide, we’ll explain how CNC coolant refractometers work, as well as .

winct-pipette

refractometer for coolant concentration

refractometer conversion chart for coolant

At Hollington Medical we specialise in the service, repair and validation of benchtop autoclaves. Operating within all medical sectors, from Chiropody to Dentistry, we are able to offer a comprehensive service built to suit you.

how to test machine coolant with a refractometer|refractometer conversion chart for coolant